The quest for sustainable energy sources has never been more urgent as global temperatures rise and conventional resources dwindle. One of the less explored yet promising areas is the utilization of waste heat—a byproduct of various processes, including human metabolism, industry, and transportation. This article delves into the innovative research that is transforming waste heat into valuable electrical energy, offering a glimpse of how our excess heat could pave the way to a more sustainable future.

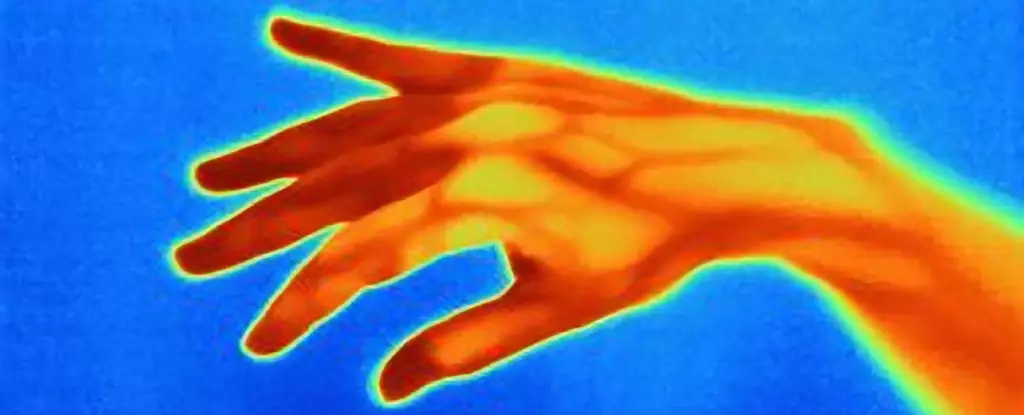

Did you know that the human body, through metabolic activity, releases significant amounts of heat? Thermal imaging reveals that we emit approximately 19 matches’ worth of heat per hour for every square foot of our body. This heat isn’t merely a side effect—it’s an extensively overlooked energy source. Imagine if wearable technologies, such as smartwatches and fitness trackers, could harness this heat energy, effectively turning our bodies into miniature power banks. Researchers are already on the path to making this a reality, developing systems that can capture, store, and utilize body heat for the sustained operation of electronic devices.

Beyond human physiology, the industrial sector generates a vast amount of waste heat daily. From the internal combustion engines of vehicles to heavy machinery in factories, industries often let this thermal energy escape into the atmosphere, missing out on a significant energy recovery opportunity. The concept of waste heat recovery aims to address this inefficiency, enabling industries to harness excess heat, enhance operational efficiency, and move toward more eco-friendly practices. Innovations in this area not only target energy conservation but also contribute to lowering greenhouse gas emissions, presenting a dual benefit for the environment and industry.

At the core of converting heat into electrical energy is the thermoelectric effect, a principle where a temperature differential generates an electric potential. While traditional thermoelectric materials like cadmium, lead, and mercury offer this capability, their environmental and health repercussions create barriers to widespread adoption. Groundbreaking research has focused on safer alternatives, including the use of renewable resources like wood. This research is pushing boundaries in how we perceive everyday materials, revealing their potential in revolutionizing energy conversion processes.

The rise of wood-derived thermoelectric materials represents a shift in energy thinking. Wood, a vital resource for human civilization, is being reimagined as a solution to harnessing industrial waste heat. A collaborative effort between the University of Limerick and the University of Valencia has identified lignin—a waste product from paper manufacturing—as a promising material for energy capture. Lignin-based membranes soaked in salt solutions can generate electricity from low-temperature waste heat, drawing on the principle of ion movement across a membrane. The results are striking; as industries generate approximately 66% of their waste heat at temperatures below 200°C, this innovation could dramatically impact energy efficiency.

The implications of this research extend far beyond theoretical applications. Factories, manufacturing plants, and other industrial entities—which routinely produce excess heat—could implement these technologies to convert waste heat into usable energy. Such innovations can lead to decreased energy consumption, lower operational costs, and reduced environmental impacts. Additionally, the technology has a wide range of potential applications—from energizing remote locations to powering various devices in everyday life. This versatility positions waste heat recovery technology as a vital player in the push toward sustainable energy infrastructures.

Capturing energy is just the beginning. The efficient storage of this energy is equally crucial for practical applications. Supercapacitors have emerged as key components in this regard, but their conventional reliance on fossil fuel-derived materials poses sustainability challenges. Recent advancements show that porous carbon derived from lignin can serve as an environmentally friendly alternative for supercapacitor electrodes. This innovation not only facilitates the effective storage of energy harvested from waste heat but also ensures that the production process remains green, eschewing chemically harmful processes associated with traditional materials.

As the world looks for sustainable energy solutions, harnessing our waste heat stands out as a practical and innovative method to generate power without additional environmental strain. From turning human body heat into energy for personal devices to capturing industrial waste heat for broader applications, the potential is vast. The ongoing research into wood-derived materials like lignin demonstrates that sustainable and efficient energy production is achievable, paving the way for a future where energy harnessing aligns seamlessly with environmental stewardship. This evolving field not only promotes energy efficiency but also beckons a paradigm shift in how we view the wastefulness of heat in our daily lives.